Iseli yelanga sisixhobo esiguqula ngokuthe ngqo amandla okukhanya kumandla ombane ngesiphumo sombane okanye isiphumo sefotochemical.Iiseli zelanga ezinefilim ezincinci ezisebenza kunye nefuthe lombane zezona ziphambili, kwaye indlela yokukhetha iiseli zelanga iyabakhathaza abanye abantu.Namhlanje, ndiza kwazisa ngokufutshane ulwazi malunga nokuthengwa kweeseli zelanga.Ndiyathemba iyakunceda.

Okwangoku, iiseli zelanga kwimarike zahlulwe kwi-silicon ye-amorphous kunye ne-crystalline silicon.Phakathi kwabo, i-silicon ye-crystalline inokwahlulwa ibe yi-silicon ye-polycrystalline kunye ne-silicon eyodwa ye-crystal.Ukuguqulwa kwe-photoelectric ukuguqulwa kwezinto ezintathu: i-silicon ye-monocrystalline (ukuya kwi-17%)> i-polycrystalline silicon (12-15%) > i-amorphous silicon (malunga ne-5%).Nangona kunjalo, i-crystalline silicon (i-crystal silicon enye kunye ne-polycrystalline silicon) ayivelisi ngoku phantsi kokukhanya okubuthathaka, kwaye i-silicon ye-amorphous ilungile ekukhanyeni okubuthathaka (amandla ekuqaleni ancinci kakhulu phantsi kokukhanya okubuthathaka).Ke xa iyonke, i-silicon ye-monocrystalline okanye i-polycrystalline silicon iiseli zelanga kufuneka zisetyenziswe.

Xa sithenga iiseli zelanga, ugxininiso lwengqwalasela ngamandla eseli yelanga.Ngokuqhelekileyo, amandla epaneli yelanga alingana nommandla we-solar wafer.Ummandla we-solar cell wafer awulingani ncam nommandla wepaneli ye-solar encapsulation, kuba nangona ezinye iipaneli zelanga zikhulu, i-wafer ye-solar enye ihlelwe kunye ne-gap ebanzi, ngoko ke amandla ephaneli yelanga enjalo ayiyimfuneko. phezulu.

Ngokuqhelekileyo, ukuphakama kwamandla epaneli yelanga, kungcono, ukwenzela ukuba i-current eveliswa elangeni inkulu, kwaye ibhetri yayo eyakhelweyo inokuhlawulwa ngokupheleleyo ngokukhawuleza.Kodwa ngokwenene, kufuneka kubekho ukulingana phakathi kwamandla epaneli yelanga kunye nokuphatheka kweshaja yelanga.Ngokuqhelekileyo kukholelwa ukuba ubuncinci bamandla otshaja belanga abukwazi ukuba ngaphantsi kwe-0.75w, kwaye iphaneli yelanga yamandla esibini inokuvelisa i-current ye-140mA phantsi kokukhanya okusemgangathweni okusemgangathweni.Umbane oveliswa kukukhanya kwelanga ngokubanzi malunga ne-100mA.Ukuba umjelo wokutshaja uncinci kakhulu ngaphantsi kwamandla esibini, ngokuqinisekileyo akuyi kubakho umphumo ocacileyo.

Ngokusetyenziswa okubanzi kweemveliso ezahlukeneyo zelanga, iiseli zelanga zisetyenziswa ngakumbi nangakumbi ebomini bethu.Kodwa phambi kwazo zonke iintlobo zeeseli zelanga kwimarike, sifanele sikhethe njani?

1. Ukukhetha umthamo webhetri yeseli yelanga

Ekubeni amandla okufakelwa kwenkqubo yokuvelisa amandla elanga ye-photovoltaic ayizinzile kakhulu, ngokuqhelekileyo kuyimfuneko ukuqwalasela inkqubo yebhetri ukuze isebenze, kwaye izibane zelanga azikho, kwaye ibhetri kufuneka ilungiselelwe ukusebenza.Ngokubanzi, kukho iibhetri ze-lead-asidi, iibhetri ze-Ni-Cd, kunye neebhetri ze-Ni-H.Ukukhethwa kwabo kwamandla kuchaphazela ngokuthe ngqo ukuthembeka kwenkqubo kunye nexabiso lenkqubo.Ukukhethwa komthamo webhetri ngokubanzi kulandela le migaqo ilandelayo: okokuqala, kwisiseko sokuba inokudibana nokukhanya ebusuku, amandla amacandelo eeseli zelanga emini kufuneka agcinwe kangangoko kunokwenzeka, kwaye kwangaxeshanye, kufuneka ukukwazi ukugcina amandla ombane ahlangabezana neemfuno eziqhubekayo zamafu kunye nezibane zokukhanya ebusuku.Umthamo webhetri uncinci kakhulu ukuhlangabezana neemfuno zokukhanya ebusuku, kwaye umthamo webhetri mkhulu kakhulu.

2. Ukukhetha ifom yokupakisha iiseli zelanga

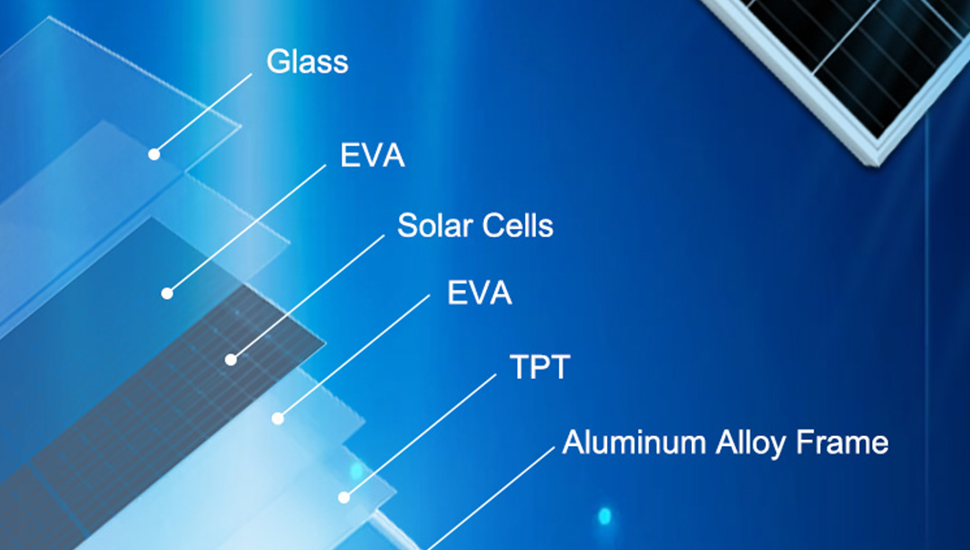

Okwangoku, kukho iindlela ezimbini eziphambili zokupakishwa kweeseli zelanga, i-lamination kunye neglue.Inkqubo ye-lamination inokuqinisekisa ubomi bokusebenza kweeseli zelanga ngaphezu kweminyaka engama-25.Nangona i-glue-bonding yayintle ngelo xesha, ubomi bokusebenza kweeseli zelanga yiminyaka eyi-1 ~ 2 kuphela.Ke ngoko, ukukhanya okunelanga eliphantsi kwamandla aphantsi kwe-1W kunokusebenzisa i-glue-drop packaging form ukuba akukho xesha liphezulu lokuphila.Kwisibane selanga kunye nobomi benkonzo obuchaziweyo, kucetyiswa ukuba usebenzise ifom yokupakisha i-laminated.Ukongeza, kukho ijeli ye-silicone esetyenziselwa ukufaka iiseli zelanga ngeglue, kwaye kuthiwa ubomi bokusebenza bungafikelela kwiminyaka eyi-10.

3. Ukukhethwa kwamandla eeseli zelanga

Amandla emveliso yeseli yelanga i-Wp esiyibiza ngamandla emveliso yeseli yelanga phantsi kweemeko eziqhelekileyo zokukhanya kwelanga, ezizezi: umgangatho we-101 ochazwe yiKhomishini yaseYurophu, ubushushu bemitha yi-1000W/m2, umgangatho womoya yi-AM1.5, kunye ubushushu bebhetri yi25°C.Le meko iphantse ifane neyelanga emini emaqanda ngemini enelanga.(Emazantsi oMlambo iYangtze, unokusondela kuphela kweli xabiso.) Oku akunjalo njengoko abanye abantu babecinga.Logama nje kukho ukukhanya kwelanga, kuya kubakho ireyithingi yamandla emveliso.Isenokusetyenziswa ngokuqhelekileyo phantsi kwezibane ze-fluorescent ebusuku.Oko kukuthi, amandla okuphuma kweseli yelanga ayenzekanga.Ngamaxesha ahlukeneyo kunye neendawo ezahlukeneyo, amandla okuphuma kweseli efanayo yelanga ahlukile.Idatha yokukhanya kwelanga, phakathi kwe-aesthetics kunye nokugcinwa kwamandla, ininzi yabo ikhetha ukugcinwa kwamandla.

Ixesha lokuposa: Jul-08-2022